PVDF is a pure semi-crystalline homopolymer containing about 59% fluorine.

PVDF crystallinity degree was chosen to obtain excellent properties, such as gas impermeability or very low swelling in certain solvents, while maintaining a very high shock resistance and high dimensional stability.

PVDF can be used in a wide temperature range (-50 ° C to + 150 ° C). It is hardly flammable (classification UL 94: VO in 0.8 mm thickness), and is easily implemented with injection machines, extrusion, quite classical.

From standard elements produced by extrusion or compression, it is possible to make voluminous or complex parts with PVDF with machining methods, boiler making ...

Applications

The petrochemical, chemical, nuclear, paper and pharmaceutical industries use PVDF because of its resistance to chemicals and ionizing radiation, for multiple applications. It is also used by the electrical and electronic industries for various parts.

In the form of a film or used in paint formulations, PVDF also finds its place in the building and transport industries. Here, are utilized its durability and corrosion protection properties. In addition, PVDF coatings are anti-fouling and anti-graffiti.

Thanks to its thermal and chemical stability, its good resistance to shocks and its impermeability, PVDF solves many problems of conditioning of fragile or corrosive products. It is used, for example, to produce bottles for transporting liquid bromine.

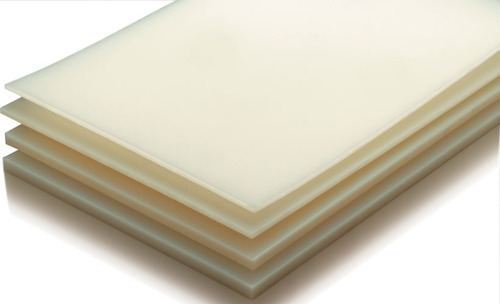

Dimensions and thickness

Sheets

|

THICKNESS (mm) |

SIZE (mm) |

|

2 ; 3 ; 4 ; 5 ; 6 ; 8 ; 10 |

2000 x 1000 |

|

10 ; 12 ; 15 ; 20 ; 25 ; 30 ; 40 ; 50 ; 60 |

2000 x 500 |

Rods

|

DIAMETER (mm) |

LENGTH (mm) |

|

10 ; 15 : 20 ; 25 ; 30 ; 35 ; 40 ; 45 ; 50 ; 55 ; 60 ; 65 ; 70 ; 75 ; 80 ; 90 ; 100 ; 110 ; 120 |

2000 |

|

135 ; 140 ; 150 ; 175 ; 200 |

1000 |

Tubes

|

DIAMETER (mm) |

LENGTH (mm) |

|

|

16 x 13 |

50 x 54,2 |

5000 |

|

20 x 16,2 |

63 x 57 |

|

|

25 x 21,2 |

75 x 67.8 |

|

|

32 x 27,2 |

90 x 91.4 |

|

|

40 x 45,2 |

110 x 99.4 |

|